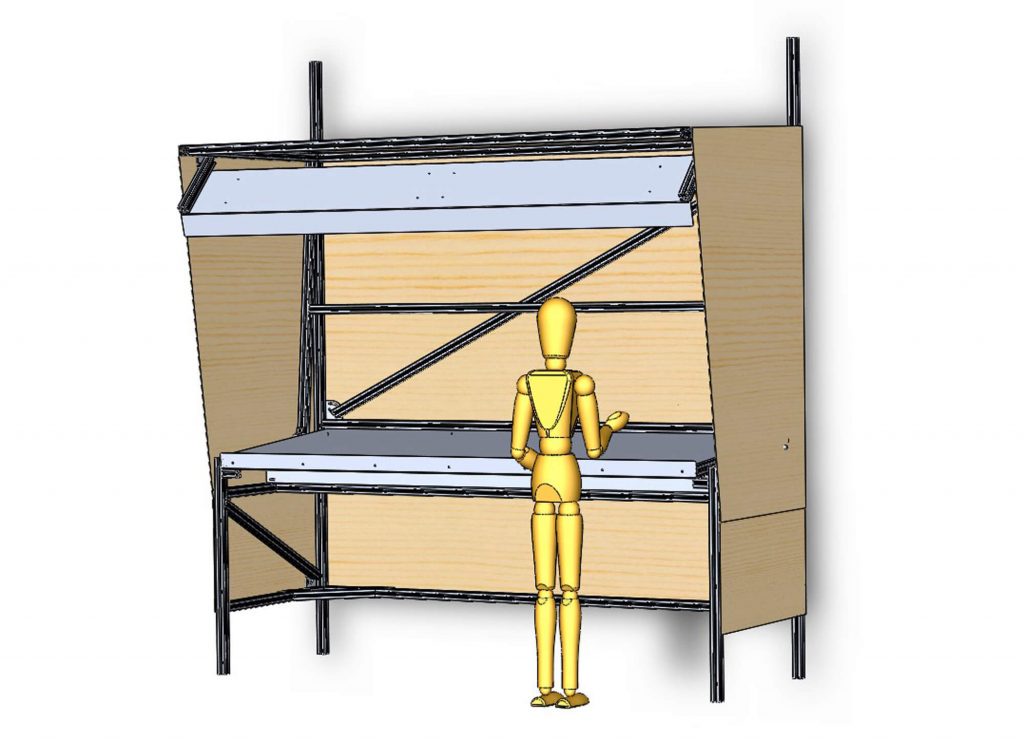

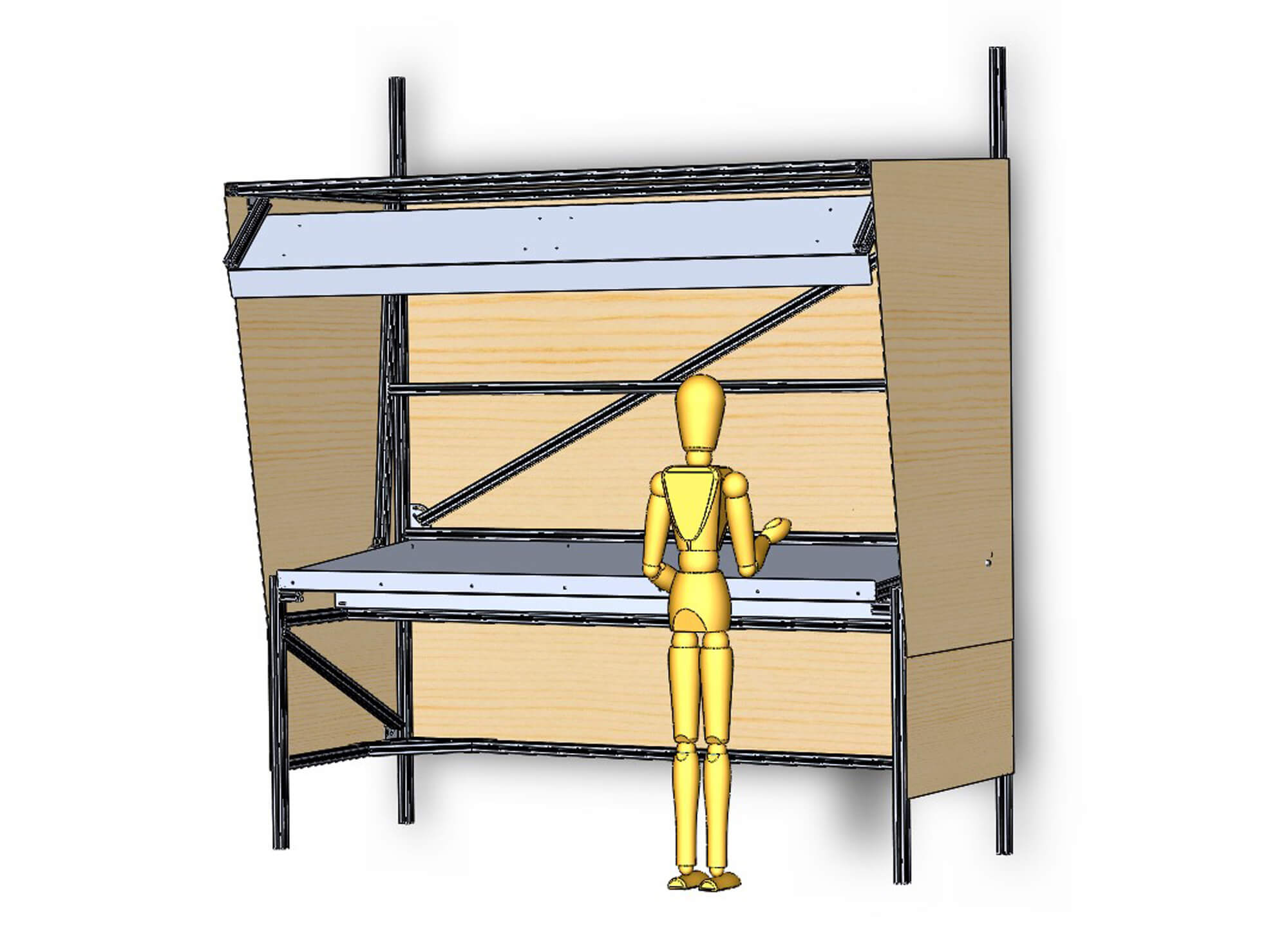

Designing a light booth for manual colour inspection of elevated prints was an assignment I received during my internships at Arius Technology in Vancouver.

Engineering undergraduate students at the University of Victoria are required to complete four three-month co-op internships. I had the luck of being able to complete two of my four co-op worker terms at Arius Technology, which at the time was a young tech startup in the art industry. Today, the company remains focused on art creation, preservation, and distribution. Its art replication and creation products and services focus on using a three-dimensional colour scanner that they originally developed for forensic analysis of the Mona Lisa. Accurately reproducing fine artwork is not as simple as scanning and printing it. There is a lot of research and design that went into the company’s scanner and the entire process they use to reproduce and create fine artwork.

Colour-managed workflows are commonplace in the printing industry. However, the combination of colour and three-dimensionality presents some unique challenges for the visual inspection stage of the process. Designing a neutral, uniform light environment for this process at Arius required that I research international standards, learn about light and optics, and employ my full knowledge of the engineering design process to create an appropriate solution which I then presented to the engineering team. After several revisions, the light booth was built within the required budget and has been serving the company well.

To get more information about Arius technology, visit their website, linked here:

https://www.ariustechnology.com/