Building a mechatronic sorting device was the practical portion of an upper-level technical elective I took as part of my undergraduate degree. The “mechatronics” course was designed to introduce mechanical engineering students to mechatronic systems, teach them the relevant theory, and give them an opportunity to put their knowledge into practice. In groups of two, every student attended a set of lab sections teaching them the basics about microcontroller programming, circuit building, and the use of sensors and actuators.

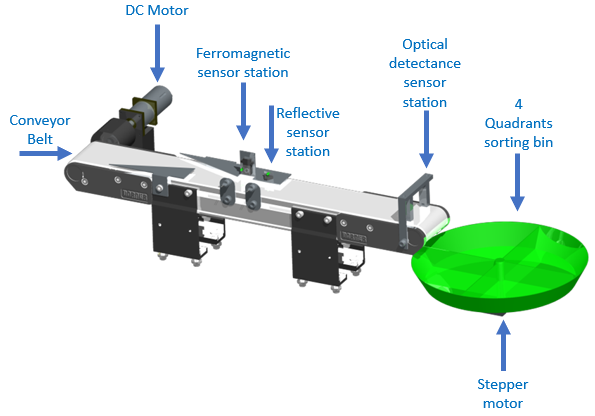

After the set of introductory labs, students were assigned the task of planning, designing, and building a mechatronic sorting system using a supplied apparatus. The assignment required students to build a better understanding of mechatronic systems while completing the following tasks:

- Generate and implement a control system for digital inlet, outlet, and homing sensors; the reflectivity analogue sensor; and the DC drive, and stepper sorting motors.

- Generate and implement a sensor calibration procedure for data validation.

- Understand and implement PWM (pulse width modulation) signals to control a DC belt drive motor.

- Understand and implement a stepper motor drive function with a useful acceleration curve.

This project, of all the projects I completed during my undergraduate degree, had the steepest learning curve. Most of the learning for the project was done independently, with a heavy reliance on interpreting technical documentation for the microcontroller and system components. It was, however, perhaps also the most rewarding. Not only did I learn about mechatronic systems; I also learnt how to gain a deep understanding of a topic and put it into practice rapidly and effectively.